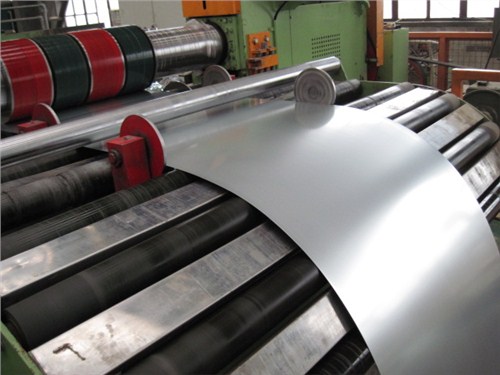

用热轧钢卷为原料,经酸洗去除氧化皮后进行冷连轧,其成品为轧硬卷,由于连续冷变形引起的冷作硬化使轧硬卷的强度、硬度上升、韧塑指标下降,因此冲压性能将恶化,只能用于简单变形的零件。轧硬卷可作为热镀锌厂的原料,因为热镀锌机组均设置有退 火线。轧硬卷重一般在20-40吨,钢卷在常温下,对热轧酸洗卷进行连续轧制。内径为610mm。又因为没有经过退火处理,其硬度很高(HRB大于90),机械加工性能极差,只能进行简单的有方向性的小于90度的折弯加工(垂直于卷取方向)。简单点儿来说,冷轧,是在热轧板卷的基础上加工轧制出来的,一般来讲是热轧---酸洗---冷轧这样的加工过程。冷轧是在常温状态下由热轧板加工而成,虽然在加工过程因为轧制也会使钢板升温,尽管如此还是叫冷轧。由于热轧经过连续冷变型而成的冷轧,在机械性能比较差,硬度太高。必须经过退火才能恢复其机械性能,没有退火的叫轧硬卷。轧硬卷一般是用来做无需折弯,拉伸的产品,1.0以下厚度轧硬的运气好的两边或者四边折弯。

轧硬卷 唐山轧硬卷 镀锌带钢 酸洗带钢就选唐山京津冷轧镀锌有限公司

The straight coil belongs to the hot rolling coil, which uses the continuous casting slab or the primary rolling slab as the raw material, is heated by the step-by-step heating furnace, enters the roughing mill after the high-pressure water descaling, and the roughing mill enters the finishing mill after the cutting head, tail and then, implements the computer-controlled rolling. After the final rolling, the straight coil is formed by the laminar cooling (the computer controls the cooling rate) and coiler coiling. The head and tail of the straight hair curl are usually in the shape of tongue and fish tail, and the accuracy of thickness and width is poor. The coil is heavy and its inner diameter is 760mm. (generally, the industry likes to use it. )Hot rolled products are widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries because of their high strength, good toughness, easy processing and good weldability. Hot rolling steel plate products include steel strip (roll) and steel plate with its shear. The steel strip (roll) can be divided into straight hair roll and finishing roll (divided roll, flat roll and longitudinal cut roll). Knowledge of rolling hard coil rolling hard coil: continuous rolling of hot-rolled pickling coil at normal temperature. Features: because it has not been annealed, its hardness is very high (HRB is greater than 90), and its machining performance is very poor, so it can only carry out simple bending processing with directivity less than 90 degrees (perpendicular to coiling direction). Application scope: (1) after annealing, it is processed into common cold rolling; (2) galvanizing unit with annealing pretreatment device is used to process galvanizing; (3) panel which basically does not need to be processed.

Definition of medium and thick plate: the thickness of steel plate is greater than or equal to 5.0mm. It includes common carbon plate, excellent carbon plate, low alloy plate, ship plate, bridge plate, boiler plate, vessel plate, etc. Application: used in construction, machinery, shipbuilding, bridges, boilers, pressure vessels and other industries.

The hot-rolled steel coil is used as raw material, the oxide skin is removed by acid pickling and then cold continuous rolling is carried out. The finished product is hard rolled coil. Due to the cold work hardening caused by continuous cold deformation, the strength, hardness and toughness plastic index of hard rolled coil increase, so the stamping performance will deteriorate and can only be used for simple deformed parts. The hard rolled coil can be used as the raw material of the hot-dip galvanizing plant, because the hot-dip galvanizing units are equipped with annealing lines. The weight of hard rolled coil is generally 20-40 tons, and the hot-rolled pickling coil is continuously rolled under normal temperature. The inner diameter is 610mm. Because of its high hardness (HRB greater than 90) and poor machining performance without annealing treatment, it can only carry out simple bending with directivity less than 90 degrees (perpendicular to coiling direction). To put it simply, cold rolling is based on the hot-rolled strip. Generally speaking, it is a process of hot rolling - Pickling - cold rolling. Cold rolling is made of hot-rolled plate at room temperature. Although in the process of rolling, the plate will also heat up, it is still called cold rolling. As a result of continuous cold rolling after hot rolling, the mechanical properties of cold rolling are relatively poor and the hardness is too high. The mechanical properties can only be restored after annealing. The one without annealing is called hard roll. The hard roll is generally used to make products without bending and stretching, and the lucky two sides or four sides with thickness less than 1.0 are bent.

Tangshan Jingjin cold rolling galvanizing Co., Ltd. is the first choice for pickling strip

直发卷属热轧卷 热轧卷是用连铸板坯或初轧板坯作原料,经步进式加热炉加热,高压水除鳞后进入粗轧机,粗轧料经切头、尾、再进入精轧机,实施计算机控制轧制,终轧后即经过层流冷却(计算机控制冷却速率)和卷取机卷取、成为直发卷。直发卷的头、尾往往呈舌状及鱼尾状,厚度、宽度精度较差,边部常存在浪形、折边、塔形等缺陷。其卷重较重、钢卷内径为760mm。(一般制管行业喜欢使用。) 热轧产品具有强度高、韧性好、易于加工成型及良好的可焊接性等优良性能,因而被广泛用于船舶、汽车、桥梁、建筑、机械、压力容器等制造行业。 热连轧钢板产品包括钢带(卷)及有其剪切而成的钢板。而钢带(卷)可以分为直发卷及精整卷(分卷、平整卷及纵切卷)。轧硬卷知识轧硬卷:在常温下,对热轧酸洗卷进行连续轧制。 特点:因为没有经过退火处理,其硬度很高(HRB大于90),机械加工性能差,只能进行简单的有方向性的小于90度的折弯加工(垂直于卷取方向)。 应用范围: (1)退火后加工成普通冷轧; (2)有退火前处理装置的镀锌机组加工镀锌; (3)基本不需要加工的面板。

直发卷属热轧卷 热轧卷是用连铸板坯或初轧板坯作原料,经步进式加热炉加热,高压水除鳞后进入粗轧机,粗轧料经切头、尾、再进入精轧机,实施计算机控制轧制,终轧后即经过层流冷却(计算机控制冷却速率)和卷取机卷取、成为直发卷。直发卷的头、尾往往呈舌状及鱼尾状,厚度、宽度精度较差,边部常存在浪形、折边、塔形等缺陷。其卷重较重、钢卷内径为760mm。(一般制管行业喜欢使用。) 热轧产品具有强度高、韧性好、易于加工成型及良好的可焊接性等优良性能,因而被广泛用于船舶、汽车、桥梁、建筑、机械、压力容器等制造行业。 热连轧钢板产品包括钢带(卷)及有其剪切而成的钢板。而钢带(卷)可以分为直发卷及精整卷(分卷、平整卷及纵切卷)。轧硬卷知识轧硬卷:在常温下,对热轧酸洗卷进行连续轧制。 特点:因为没有经过退火处理,其硬度很高(HRB大于90),机械加工性能差,只能进行简单的有方向性的小于90度的折弯加工(垂直于卷取方向)。 应用范围: (1)退火后加工成普通冷轧; (2)有退火前处理装置的镀锌机组加工镀锌; (3)基本不需要加工的面板。

中厚板定义:钢板厚度大于等于5.0mm。 分普碳板、优碳板、低合金板、船板、桥梁板、锅炉板、容器板等。 用途:应用于建筑、机械、造船、桥梁、锅炉、压力容器等行业。

用热轧钢卷为原料,经酸洗去除氧化皮后进行冷连轧,其成品为轧硬卷,由于连续冷变形引起的冷作硬化使轧硬卷的强度、硬度上升、韧塑指标下降,因此冲压性能将恶化,只能用于简单变形的零件。轧硬卷可作为热镀锌厂的原料,因为热镀锌机组均设置有退 火线。轧硬卷重一般在20-40吨,钢卷在常温下,对热轧酸洗卷进行连续轧制。内径为610mm。又因为没有经过退火处理,其硬度很高(HRB大于90),机械加工性能差,只能进行简单的有方向性的小于90度的折弯加工(垂直于卷取方向)。简单点儿来说,冷轧,是在热轧板卷的基础上加工轧制出来的,一般来讲是热轧---酸洗---冷轧这样的加工过程。冷轧是在常温状态下由热轧板加工而成,虽然在加工过程因为轧制也会使钢板升温,尽管如此还是叫冷轧。由于热轧经过连续冷变型而成的冷轧,在机械性能比较差,硬度太高。经过退火才能恢复其机械性能,没有退火的叫轧硬卷。轧硬卷一般是用来做无需折弯,拉伸的产品,1.0以下厚度轧硬的运气好的两边或者四边折弯。

轧硬卷 唐山轧硬卷 镀锌带钢 酸洗带钢就选唐山京津冷轧镀锌有限公司